GH-SPN-120 GodHand Ultimate Nipper

GH-SPN-120 GodHand Ultimate Nipper

Couldn't load pickup availability

Description

Ultra thin single edged! Ultimate Sharpness!

Ultra thin single edged brings excellent performance with less work time!

Ultimate nipper is designed for the gate cut by pursuing the ultimate cut.

When trying to slice and cut the 3mm runner, the blade will move freely and smoothly without any noise.

“Shave & Cut” structure allows a smooth cut surface as if it is cut off by a design knife and it minimizes plastic whitening.

Compared to a standard nipper, the section that is cut has a clean surface which is beneficial to those who want to finish the plastic models without painting.

The cut section is smooth

The cut section is rough Comparing to a standard nipper’s cut section. (We use GN-125)

For people who paint plastic models, this is the best nipper to use because when they cut along the edge, it leaves no remains of the gate. It leaves with a clean cut section. This shortens the time spent on filing the gate.

When cutting small parts, it will not fly away. It will decrease the amount of time spent searching for the fly away parts.

Ultimate nipper not only does it save time but also require less work.

To cut off a 3mm plastic, the Ultimate nipper only requires a force of 2kg when a normal nipper requires a force of 3.5-10kg.

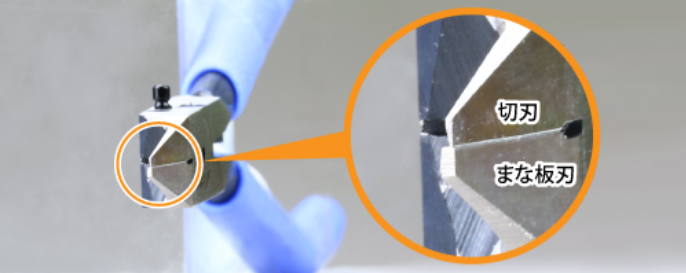

Cutting Blade and “Single-Edged Structure” striving for clean cutting.

The ultimate nipper consists of the cutting blade and the single edged structure which creates super clean cutting surface.

Ultra-thin “cutting blade” by craftsmanship

The essence of Ultimate Nipper is the thin and sharp like knife, “Cutting Edge”.

Ultra-thin “cutting edge” is created one by one by a well experienced craftsmanship in Tsubame-Sanjo, Niigata prefecture, Japan.

Single Edged Structure for a cleaner cut.

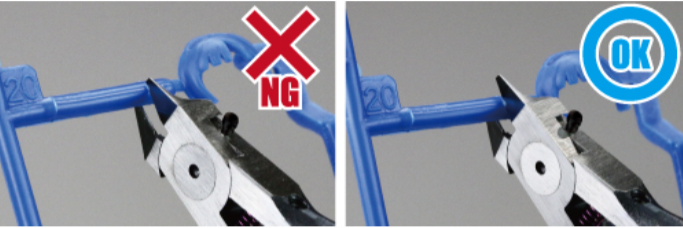

For a cleaner cut section, we chose a “Single Edged Structure” for the Ultimate Nipper.

Single Edged Structure is where one blade is the “Cutting Edge” and the other blade is the “Cutting board Edge”, like a knife and a cutting board.

Only one blade has an edge (cutting blade), so it is called “Single Edged”.

Cutting blade/ Object/ Cutting board edge.

The wide cutting board edge firmly supports an object

By gripping…

The cutting edge cut an object.

The cutting board edge supports an object firmly while the gripping force changes to move the cutting edge smoothly.

The wide cutting board edge supports an object firmly leading to minimum deformaties due to cutting.

The cutting board edge plays an important role to cut off accurately.

The cutting board edge protrudes a bit from the cutting edge.

As a result, there will remain a very small part of the gate.

This is because “accurately cutting” is prioritized than having a flat cut section.

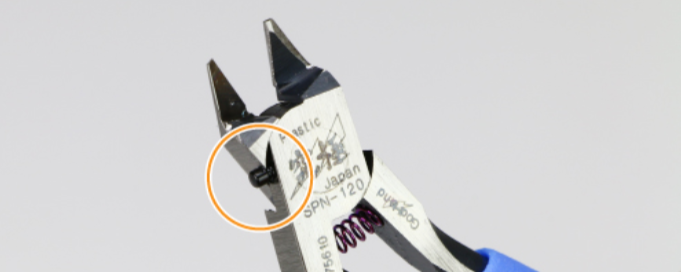

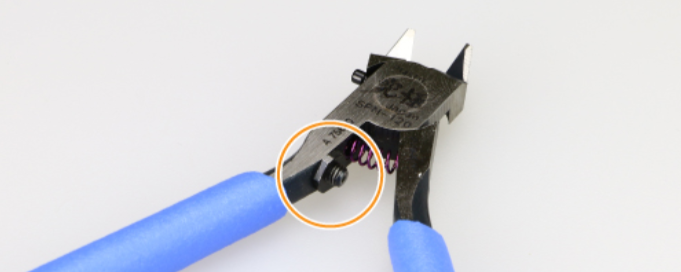

Any nipper will become loose as it gets old.

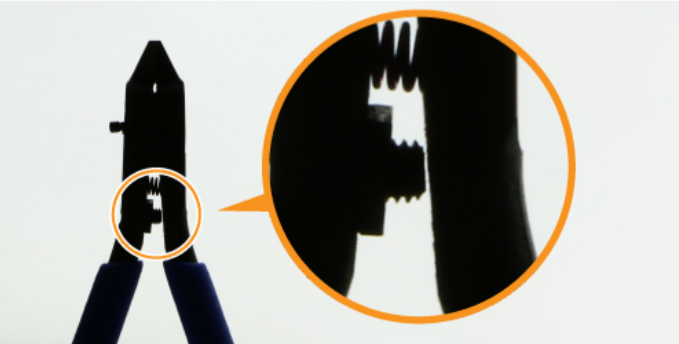

If the cutting edge and the cutting board edge are aligned, even the slightest misuse will result in the edges being off.

If the cutting board edge and cutting edge are aligned…

If the nipper gets loose,

Both blades are not aligned resulting in an unclean cut.

When the cutting edge and the cutting board edge are not aligned, it will result in an unclean cut and possible

chipping and breaking of the blades.

In order to avoid this situation, the cutting edge board has a wider range so that when it deteriorates and gets

loose, it will still allow for proper function.

If the cutting blade touches the center of the cutting board blade…

Even if the nipper gets loose,

The blades will still touch even with a slight misalignment

Can completely cut off objects with high quaility.

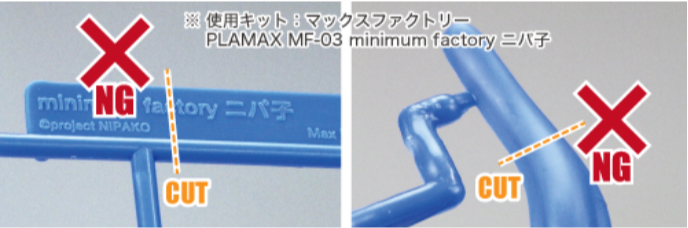

On the other hand, the cutting board edge and the cutting edge are not flat so a small gate might remain even if you align the blade along the gate and cut.

Share